How Apple Watch is made

From product designer Greg Koenig, a fantastic display of Kremlinology on how he thinks Apple makes the Apple Watch, based on the available evidence (production videos, patents, product specs).

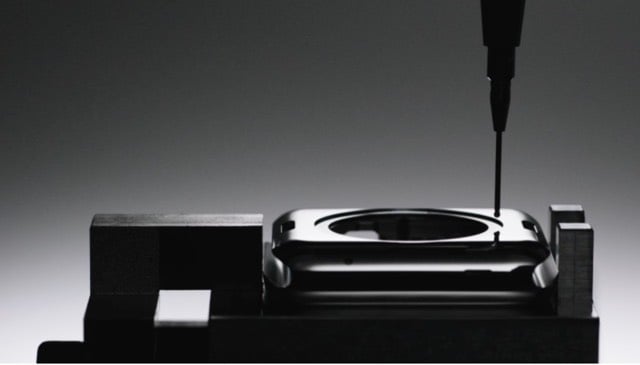

In the above shot, blanks are placed in an immersion ultrasonic tester. What Apple is looking for is the presence of voids or density variances within the structure of the blank that, under stress, could lead to part failure or surface defects as material is removed in further machining processes. This level of inspection is, to put it mildly, fastidious beyond where most other companies would go (save Rolex). Immersion ultrasonic inspection is typically reserved for highly stressed medical implants and rotating components inside of aircraft engines; not only does this step take time, it also is typically performed by custom built machines of tremendous expense.

If you don’t have the time or energy to read through the whole thing, at least skip to the final two paragraphs about manufacturing as ritual.

Also, Koenig’s Twitter stream is full of interesting nuggets about Apple. Here are a few that caught my attention:

If you want a preview of how Swiss watch companies will face off Tech companies in watches, look at Leica.

— Greg Koenig (@gak_pdx) March 20, 2015FYI- Now is about the time iPhone 6s first article samples are rolling off production lines.

Think about that,

— Greg Koenig (@gak_pdx) March 19, 2015The Apple Watch has as much to do with watches as an iPhone has to do with being a phone.

— Greg Koenig (@gak_pdx) March 11, 2015“It’s a phone, an iPod and an internet communicator” Of those 3 original tentpoles, 2 are nearly irrelevant.

— Greg Koenig (@gak_pdx) March 11, 2015

Stay Connected